Product details

Charcoal production process description

1, Wood Crushing Process

Hammer Mill can crush the log, risk husk etc into powder.

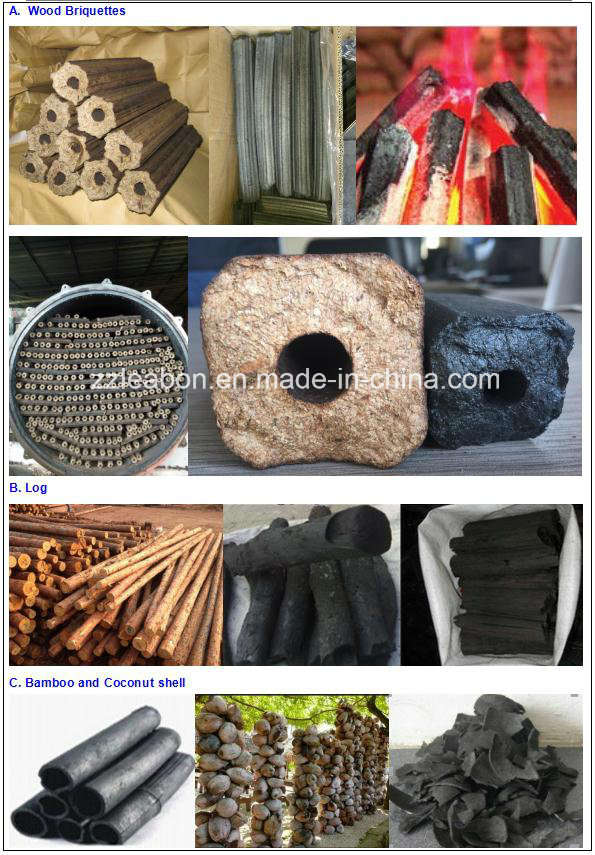

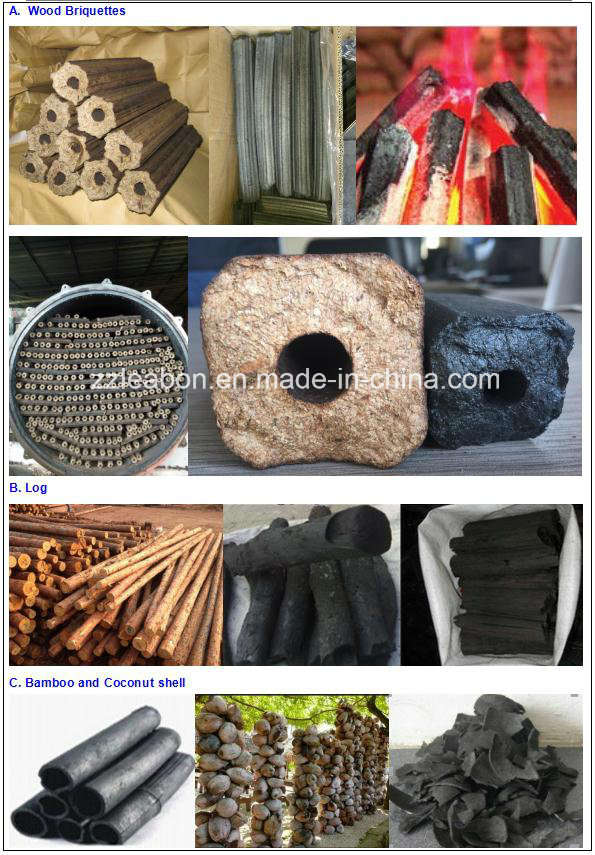

2, Briquette making system process:

Cyclone collected sawdust after drying by the conveyor belt into the storage silo by screw conveyor into the fabric of automation systems, automated feeding system even after drying the sawdust to feed six rods machines, rods later, stick out from the conveyor belt conveyor. Flue rods produced by the discharge pipe plant with fan.

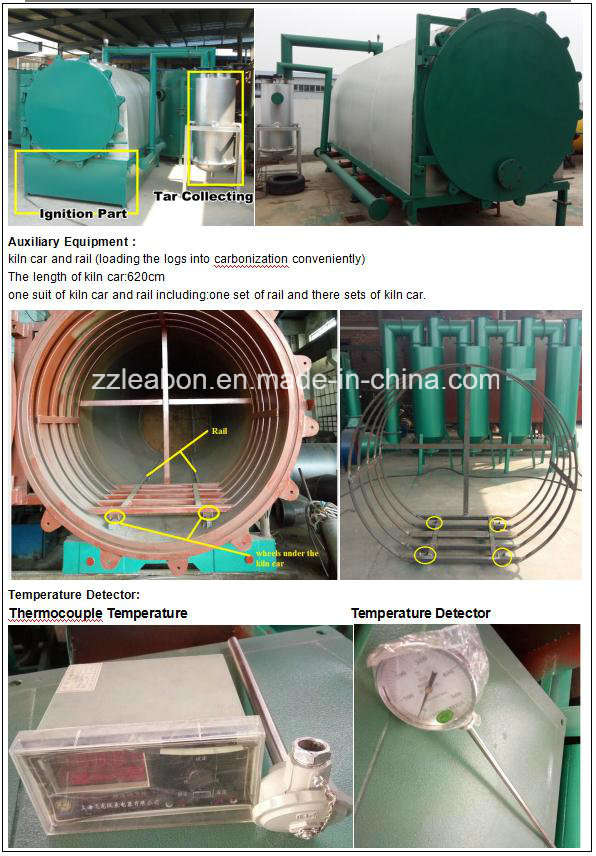

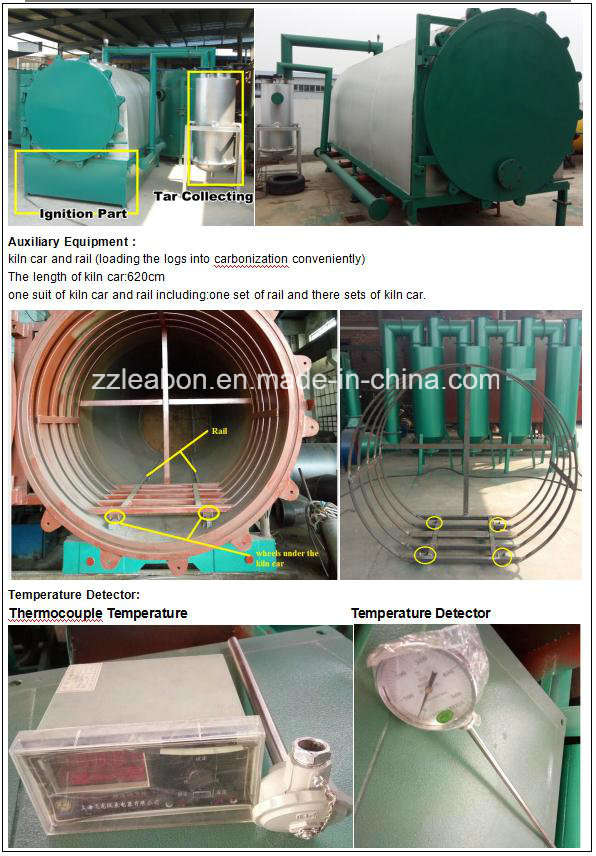

3, Carbonizing process

The moladed briquette attached to the furnace charring furnace sealed, lifted into the furnace body ignited charcoal quality according to temperature control, after completion of the carbonization furnace hoisting out, wait charcoal cooling into cartons warehouse.

If you want to know more about the line, please feel free to contact me.

Company Profile

Company Profile